Let’s talk about what actually goes into making a mine “smart.” Not the marketing version. Not the keynote-speech version. The nuts-and-bolts version, where drones fly grid patterns over active excavation sites, terabytes of point-cloud data get stitched into navigable 3D terrain, and fleet telemetry streams merge with geological models in real time.

That’s the project Virtu delivered for Petrosea. And the reason it’s worth examining in detail is that it tackles the three hardest problems in mining visibility simultaneously: accurate terrain modeling, live asset tracking, and accessible multi-platform delivery.

Building Terrain from Laser Pulses

Traditional topographic surveys take weeks and are outdated almost immediately in an active mine. Virtu replaced that cycle with drone-based LiDAR capture. Drones equipped with LiDAR sensors flew systematic patterns over Petrosea’s sites, collecting millions of georeferenced data points per flight.

The raw point clouds were processed into detailed 3D surface models—not just contour lines on a flat map, but actual geometric representations of pit walls, ramps, haul roads, and stockpile areas. More importantly, Virtu baked in a predictive layer. Using excavation plans and historical dig rates, the digital terrain could project what the mine would look like weeks or months ahead. Planners didn’t just see today’s mine—they could preview tomorrow’s.

Plugging the Fleet into the Model

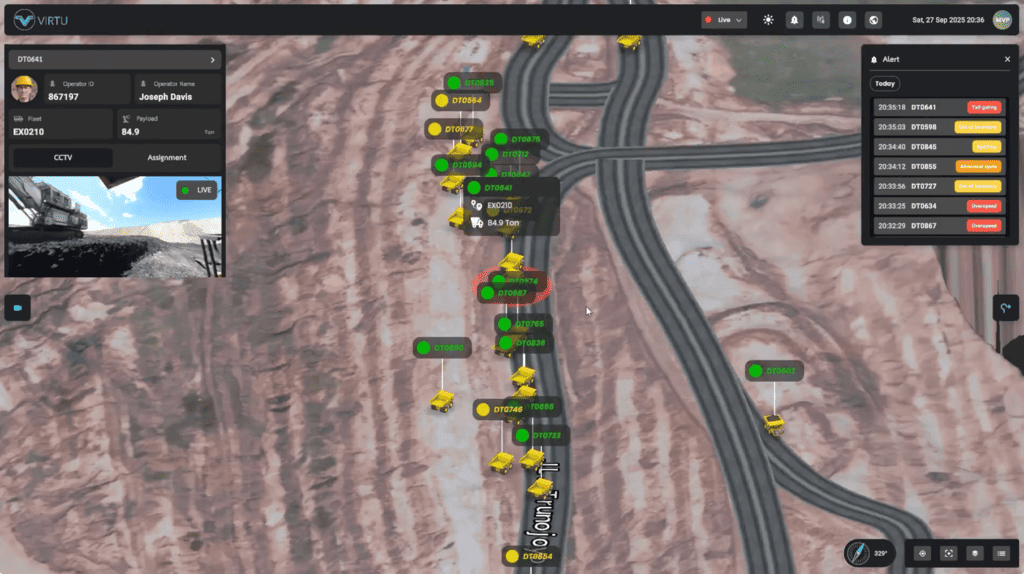

A terrain model without operational data is like a city map without traffic. Useful for orientation, useless for logistics. Virtu connected Petrosea’s Fleet Management System directly into the digital twin, feeding vehicle positions, speeds, payloads, and status codes onto the 3D terrain in real time.

The effect was immediate and practical. Dispatchers could see every truck and loader as a labeled marker moving across the virtual mine. When a hauler deviated from its assigned route, the system flagged it. When a loading queue backed up at a specific pit face, the bottleneck was visible at a glance—no radio calls needed. Maintenance alerts tied to specific vehicles appeared on the map exactly where those vehicles were parked, so field mechanics knew not just which truck needed attention, but precisely where to find it.

Web, Mobile, and Mixed Reality Delivery

The smartest backend in the world means nothing if the people who need the information can’t reach it where they work. Virtu designed three delivery channels, each shaped around a different user context.

The web interface served corporate and regional managers who needed the full analytical picture from their desks. The mobile app gave on-site supervisors a pocketable window into the live mine state—ideal for quick checks between site walkthroughs. And the mixed reality experience let engineers wearing MR headsets see digital overlays projected onto the real physical environment. Standing at the edge of a pit, they could see the projected topology for next quarter, the position of the nearest active fleet assets, and alert zones—all floating in their field of view, anchored to the real landscape.

What the Mining Sector Should Take Away

What makes the Petrosea deployment compelling isn’t any single piece of technology. LiDAR, fleet telemetry, and mixed reality each exist independently. The breakthrough was in the integration—combining them into a coherent digital twin that updates continuously and serves its insights to every level of the organization through the platform each person actually uses.

For Virtu, this project established a replicable blueprint. For Petrosea, it became the new normal. And for the broader mining industry, it answered a question many were still debating: can you actually run a real digital twin on a live, large-scale mining operation? The answer is yes. Petrosea is the proof.

Contact Virtu

Website: www.virtu.co.id

Email: [email protected]

WA/ Call: +62 812-9696-7887